Mainspring calculation

Simulation & Materials

Simulation

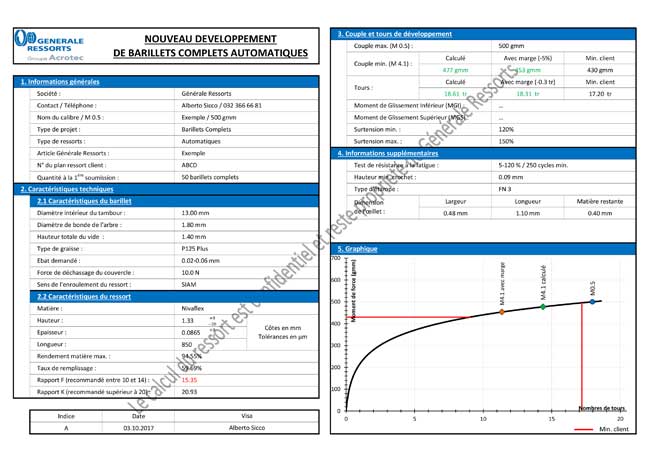

The simulation phase is the first stage necessary to define the spring geometry according to the desired torque requirements, power reserve and fatigue resistance.

The results are shared with our customers and optimised before manufacturing to therefore produce only the ideal spring.

In order to simplify customer requests, please download the form provided by Générale Ressorts below:

Form – Project ( .xls )

This simplifies the transmission of the technical data in order to estimate the feasibility of the spring and to start to quote all new developments.

You may send this completed form to our technical consultant. This request is free of charge and without any obligation.

The simulation result resumes the key data of the spring dimensions :

- Torque at M0 and M24 hours (linked to the amplitude of the balance spring)

- Number of turns (linked to the power reserve)

- Mainspring geometry

- Fatigue resistance

- Discharge curve

Nivaflex

The performance of our mainsprings is strongly influenced by the materials that we use. The NIVAFLEX® 45/18, 45/5 and the Nivaflex Plus® are multiphase alloys made of CoNiCr. The mechanical properties can be improved by precipitation hardening. By adding beryllium, the

NIVAFLEX® 45/5 variant reaches even higher resistance and hardness properties. Furthermore, excellent corrosion resistance and non magnetic behaviour make the NIVAFLEX® a unique alloy.

The Nivaflex Plus is based on an improved management of the alloy uniformity and a reduced level of impurities. The results are a of better fatigue resistance and the possibility of reaching higher deformation limits.

You can download the corresponding technical data sheets here :

Bioflex

BIOFLEX® is a multiphase alloy not containing cobalt, nickel or beryllium. It therefore fits perfectly to various international norms such as REACH. Its mechanical properties can be improved by precipitation hardening. Its excellent resistance to corrosion, non-magnetic behaviour in addition to its extreme ductility combined with its strong resistance make BIOFLEX® a high performance alloy.

The use of BIOFLEX® in the watchmaking field has been the subject of several patents by Générale Ressorts. Its application as a mainspring allows a reduction in the loss of amplitude between 0 h and 24 h and therefore an increase in chronometric stability, thanks to the reduced elastic modules compared to Nivaflex. In addition, the high resistance to deformation guarantees excellent results in terms of fatigue resistance.

You can download the corresponding technical data sheet here :

Bioflex technical data sheet